Acoustic ceilings do help to dampen noises between floors and they can be painted to match the decor of the room. One drawback with traditional acoustic ceilings is water stains from roof leaks. The pooling water can create a buckled appearance or cause an individual panel to fall out unexpectedly. Dried water stains can be very unsightly, but treatment with bleach or a special acoustic panel restorative can help. Replacing an individual panel in this type of ceiling is not especially difficult, so homeowners can always change from a finish to one with sparkles or a rough appearance.

One popular use of acoustic ceilings is an instant fix for unappealing rooms. Instead of an expensive renovation of a dilapidated ceiling, a grid can be installed in a few hours and acoustic tiles dropped in. Special fluorescent lighting panels which match the dimensions of a single grid can also be wired in minutes and dropped into place. Lowering the height of a ceiling through traditional building techniques could take days of framing, wiring and plastering. Although acoustic ceilings have been accused of being too much of a quick fix, the drop paneling system they represent is still used today as an inexpensive alternative to a complete renovation.

Acoustical ceiling tiles have been used a lot not only inside homes but also for other purposes such as inside classrooms, hospitals, studios etc. This particular type of ceiling tiles is usually done to support the functionality of the space and its design purposes. Not only that it could reduce the noise effect produced from the room, but these tiles could also create the decorative purpose that you want so that your room doesn’t look boring and dull. By using them, you will see and feel the significant effect especially for the sound interference between the different rooms in the building or inside your house.

Acoustical ceiling tiles could also be equipped with sound proof ceiling material that could help the purpose of creating a sound proof room to be even better in its appearance. The details when you install this particular type of ceiling must be taken into consideration especially with the size of the room before you purchase the materials to cover your ceiling with. The designs and styles of them need to also be paid attention for so that they are well included in your estimation of budget when you are doing the planning of decorating the room.

Acoustical ceiling tiles could also adjust the level of sound that will be produced from the room. One room might need different tiles than the others especially with its thickness in materials. Rooms such as a classroom would only need small level of background noise while offices or hospitals with more open space might need moderate and medium level of sound-proofing. This all could easily be done by incorporating this type of tiles into your ceiling to help the cause of designing those rooms not to only look appealing, but with their main functions that come with them also

Older house designs often called for very high ceilings, primarily to draw hot air away from the living space. Now, acoustic ceilings continue to be a popular choice in many offices, businesses and schools.

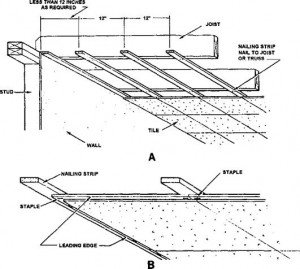

Interior designers seeking an affordable method to lower the height of a modern room and also deaden ambient noise developed acoustic ceilings. A gridwork of metal strips is hung from the room’s true ceiling and individual panels of sound-absorbing material are dropped into the sections. Heating and cooling ducts can also be hidden behind these ceilings, along with unsightly wires for overhead lighting and pipes for plumbing fixtures.

The use of acoustic ceilings reached its zenith in the 1960s through the early 1980s. In 1978, products containing asbestos were banned for home use by government regulators, and this affected the manufacture and installation of most acoustic panels in use at the time. Many homeowners hired specially-trained contractors to remove the older acoustic ceilings from their homes. Some restored the ceilings to their original dimensions, while others selected other panels without asbestos. The typical ‘popcorn’ textured ceilings also fell out of style with the advent of more stylized paneling.

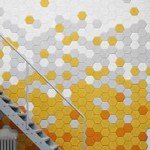

WWC – WOOD WOOL COMPOSITE PANELS / CEILINGS

ECONOMICAL AND ECO-FRIENDLY SOLUTION TO INSULATION CONCERNS.

LIGHT CONSTRUCTION BOARDS PROVIDE IMPROVED THERMAL AND SOUND INSULATION WITH THE ADDED BENEFIT OF ECO-FRIENDLINESS AND DURABILITY.

AVA has to its credit with own specifically designed products to meet the special need of the acoustics requirements. We specially get manufactured acoustic panels as per our need from the OEM suppliers which are just available with us for the specific need of the venue.

This advantage gives customer an edge and an outstanding approach to achieve the desired acoustics performance and results.

What is WWCB?

Wood Wool Cement Board is a versatile, ecologically pure and safe construction material, meeting all criteria of comfortable and safe housing.

WWCB is made of woodwool and Portland cement with addition of natural mineralizing agent.

High content of wood in WWCB makes them similar by ecological properties to wood mass, at the same time; the cement provides WWCB with durability and long service life, allows using them as a perfect construction material.

Wood wool is a band-like fibers 0,2 – 0,5mm thick, 3 – 5 mm wide and up to 25 mm long, cut on the special equipment. It has a function of filler in content of fiberboard. Due to this feature, woodwool slabs have valuable properties of timber, as a natural, ecologically pure material, its strength and perfect thermal insulation. Portland cement is water resistant and frostproof. The content of cement provides ready slabs with durability and long-term service life.

Production

Wood strands are first impregnated, and then by pressing they are bonded with cement in the continuous technological process. In this process wood strands become resistant to expanding, insects, rotting, water absorption, and fire resistance is also significantly improved. Testing has proved that the properties of WWCB improve over the years.

AVA WWCB come in 600 x 1200mm sheets and are available in 15mm,25mm, 30mm, 40mm, 50mm or 75mm thicknesses, on order WWCB are available in thicknesses ranging from 15 to 100 mm.

Properties

The main characteristics are:

- Fire resistance

- Wet and dry rot resistance

- Freeze-thaw resistance

- Termite and vermin resistance

- Thermal insulation, providing energy savings

- Acoustic performance – sound absorption

- Acceptance of a wide range of finishes

A major application of WWCB in developing countries is durable, energy efficient Economic Housing.

Fire resistance

WWCB has been tested and classified B1 (fire resistant) according to the German DIN 4102 standard.

Wet and dry rot resistance

Because the wood wool has been mineralized by the cement, moisture loses its effect on the board. The boards are used for interior and exterior applications and in moist conditions such as ceilings in indoor swimming pools

Termite and vermin resistance

Tests have proven that WWCB is not vulnerable to attack by termites or vermin, nor is WWCB subject to any biological decay.

Thermal insulation

Because of its relatively low density, WWCB has good thermal properties. The maximum thermal conductivity for boards of 25 mm thickness is 0.090 W/mK.

For 2- or 3-layer composite panels, the thermal conductivity will be further reduced, when a core of respectively rigid foam (e.g. polystyrene) or mineral fiber has been applied.

Acoustic performance

Unfinished (or spray-painted) WWCB has very good acoustic absorption properties since the open surface structure allows for a high level of sound absorption.

Finishes

Wood Wool Cement Board accepts all kinds of conventional rendering, plastering, decorative materials and mastics. Acoustic ceilings can be spray- or roll-painted while retaining its acoustic properties.